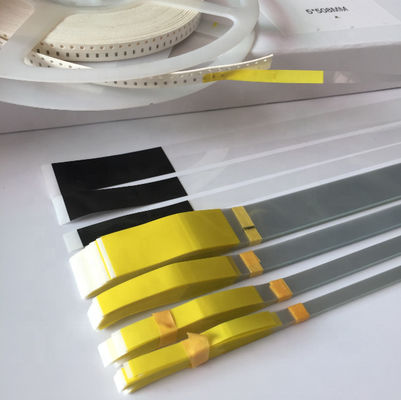

ETON over 10 years experience in SMT machines, so we are very professional to provide whole line solution.

Automatic stencil printer machine with pick and place machine, loader, conveyor, unloader, reflow oven to be one automatic line.

Automatic line save much labor cost compared with the semiautomatic line, also with higher printing precision could produce high quality electrical products. Here are the automatic SMT line solution layout:

Αφήστε ένα μήνυμα

We bellen je snel terug!

Το μήνυμά σας πρέπει να αποτελείται από 20-3.000 χαρακτήρες!

Το μήνυμά σας πρέπει να αποτελείται από 20-3.000 χαρακτήρες!

Παρακαλούμε ελέγξτε το email σας!

Παρακαλούμε ελέγξτε το email σας!

υποβολή

Περισσότερες πληροφορίες διευκολύνουν την καλύτερη επικοινωνία.

Ο κ.

- Ο κ.

- Κα

Εντάξει

Υποβλήθηκε με επιτυχία!

We bellen je snel terug!

Εντάξει

Αφήστε ένα μήνυμα

We bellen je snel terug!

Το μήνυμά σας πρέπει να αποτελείται από 20-3.000 χαρακτήρες!

Το μήνυμά σας πρέπει να αποτελείται από 20-3.000 χαρακτήρες!

Παρακαλούμε ελέγξτε το email σας!

Παρακαλούμε ελέγξτε το email σας!

υποβολή